TempLink: Revolutionizing Food Safety with Automated Temperature Monitoring

TempLink | Tharaldson Ethanol Testimonial

Revolutionizing Temperature Monitoring With Templink

TempLink | West Fargo Public Schools Testimonial

How TempLink Works

Templink Installation

Frequently Asked Questions

How Does Templink Monitoring Systems Ensure Food Safety?

Why Is Food Safety Important?

Why Is a Food Safety Plan Important?

Why Is Monitoring Food Safety Important?

What Is HACCP?

Why Do I Need an Automated Food Monitoring System?

What Is Digital Food Safety?

Do You Have a Video Demonstrating How Templink Monitoring Solutions works?

Why Choose Templink Monitoring Solutions?

Templink Monitoring Solutions is a leader in food service, and many industries in cold storage monitoring technology. Our system is designed to help your business tackle the challenges of rising food costs, labor shortages and inefficiencies in regulatory compliance protocols.

Our Easy-to-Use Platform Combines:

• Automated Temperature sensor monitoring 24/7 – 365 Days

• Real-time alerts

• Comprehensive data monitoring and reporting

Templink Monitoring Solutions empowers you and your staff to work more efficiently, streamlining daily tasks while enhancing awareness of your equipment’s performance, ultimately ensuring better food safety and operational efficiency. All of this is designed to help you, and your staff work more efficiently, increasing performance and overall operational health.

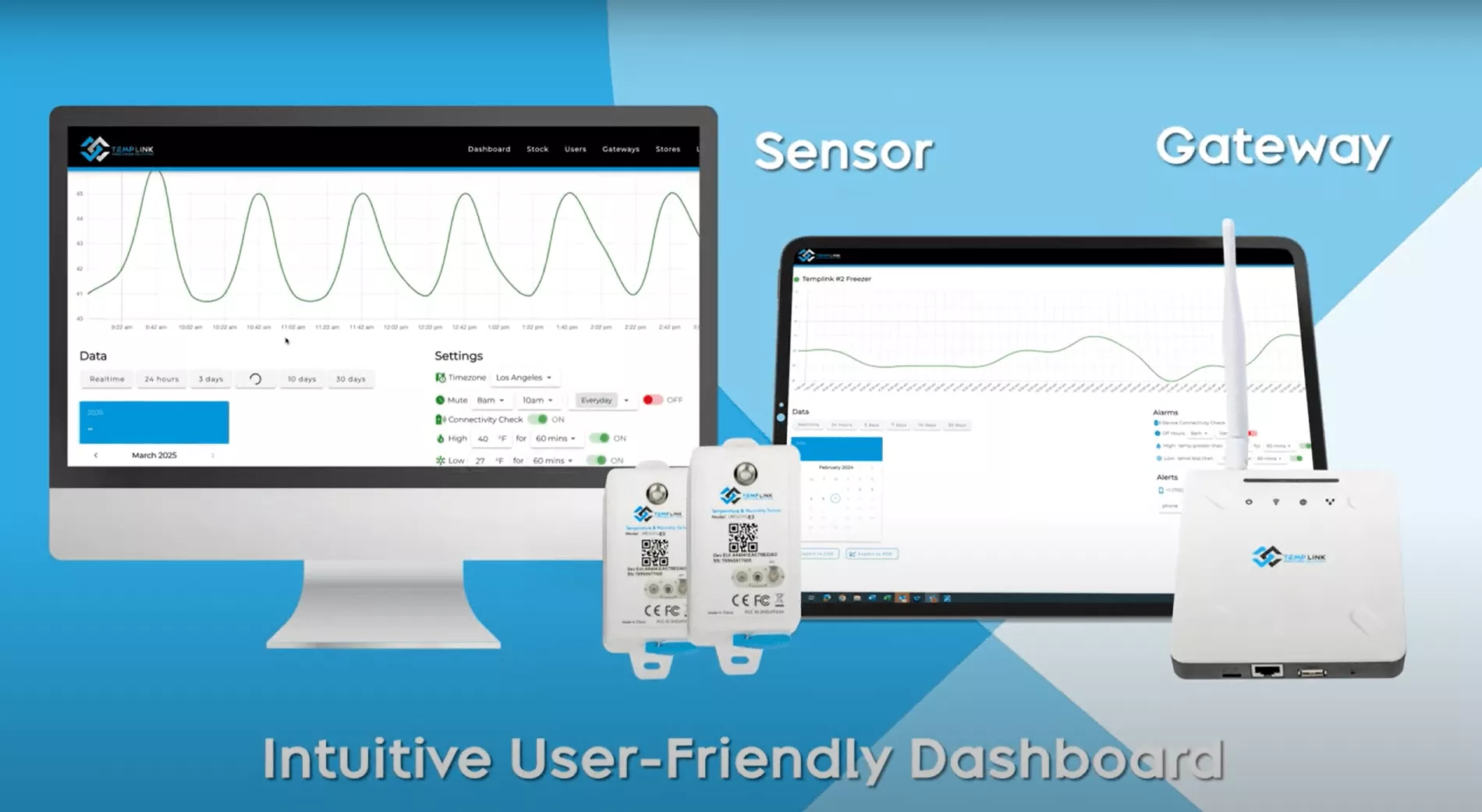

Is The System User-Friendly?

Definitely! The system is designed with ease of use in mind. Users can be trained quickly, often up to speed in as little as 90 seconds. All collected data is displayed on an intuitive sorted dashboard, allowing you to easily track task completion and ensure that coolers and other equipment are operating within the proper parameters.

Templink Monitoring Solutions uses IoT LoRaWAN Gateway Technology

- Data Collection & Storage: LoRaWAN technology collects and stores all your data, ensuring seamless temperature monitoring.

- Wireless Sensor Integration: Paired with wireless sensors, the receiver logs temperature data and transmits it to the cloud. This allows you to easily view temperature readings in real time and receive timely alerts as needed.

- Power Outage Protection: In the event of a power outage, the wireless receiver continues to record and store temperature data immediately transmitting it once access is restored.

- LoRaWAN – Long-Range, Low-Power IoT Technology: Templink Monitoring Solutions utilizes LoRaWAN long-range, low-power sensors for temperature tracking. LoRaWAN signals can travel farther even through thick, insulated equipment and buildings—while using significantly less power. This extends equipment lifespan, reduces maintenance needs, and provides more flexible installation options with smaller sensors. They are battery-powered, easy to install, and don’t require drilling. Add them to any walk-in coolers, freezers, or equipment in your kitchen.

Is There a Limit to How Many (LoRaWAN?) Sensors I Can Use?

What Kind of Real-Time Alerts Do Templink Monitoring Solutions Offer?

You can customize your alert preferences, including the notification method(s) and alarm escalation process. Choose from email, text, 24/7 – 365 days a year.

For example, if your LoRaWAN sensors detect unsafe storage conditions due to power loss or equipment failure, our 24/7 – 365 days a year monitoring will immediately contact the designated manager or supervisor to take corrective actions ensuring prompt remediation to prevent food loss.

How long is the battery life of your sensors?

How Many Locations Can I Manage Remotely Through the Dashboard?

Are Templink Monitoring Solutions Easy to Install?

Yes! Templink Monitoring Solutions is a self-install, plug-and-play wireless temperature monitoring system. It requires a power source and Ethernet connectivity to get up and running.

Onboarding & On-Going Support

We have dedicated onboarding specialists to assist with your specific installations, and our full customer service team is available to support you at any time after installation is complete.

Will training be provided?

Definitely! Your sales representative and onboarding specialist will provide comprehensive documentation and video training, customized to meet the unique needs of your business.

Is there an App for Templink Monitoring Solutions?

How much does Templink Monitoring Solutions cost?

The system consists of two main components:

- Temperature Sensors

- Automated Temperature Monitoring

Pricing Details

A one-time equipment fee, tailored to the size and needs of your operation.

An annual subscription fee that covers 24/7 monitoring and real-time alerts.

What If I Have a Problem with My Templink Monitoring System?

Our support team is available any time. You can reach us by phone at 1-844-962-3500 or via email at [email protected].

Can I get a demo of the Templink Monitoring Solutions system before purchasing?

Definitely! Click here to schedule your personalized live demo with a Templink Sales Representative.